Prefabricated Modular Restaurant Diner Room, Mobile Shop, Store House with Aluminum Door Aluminum Windows

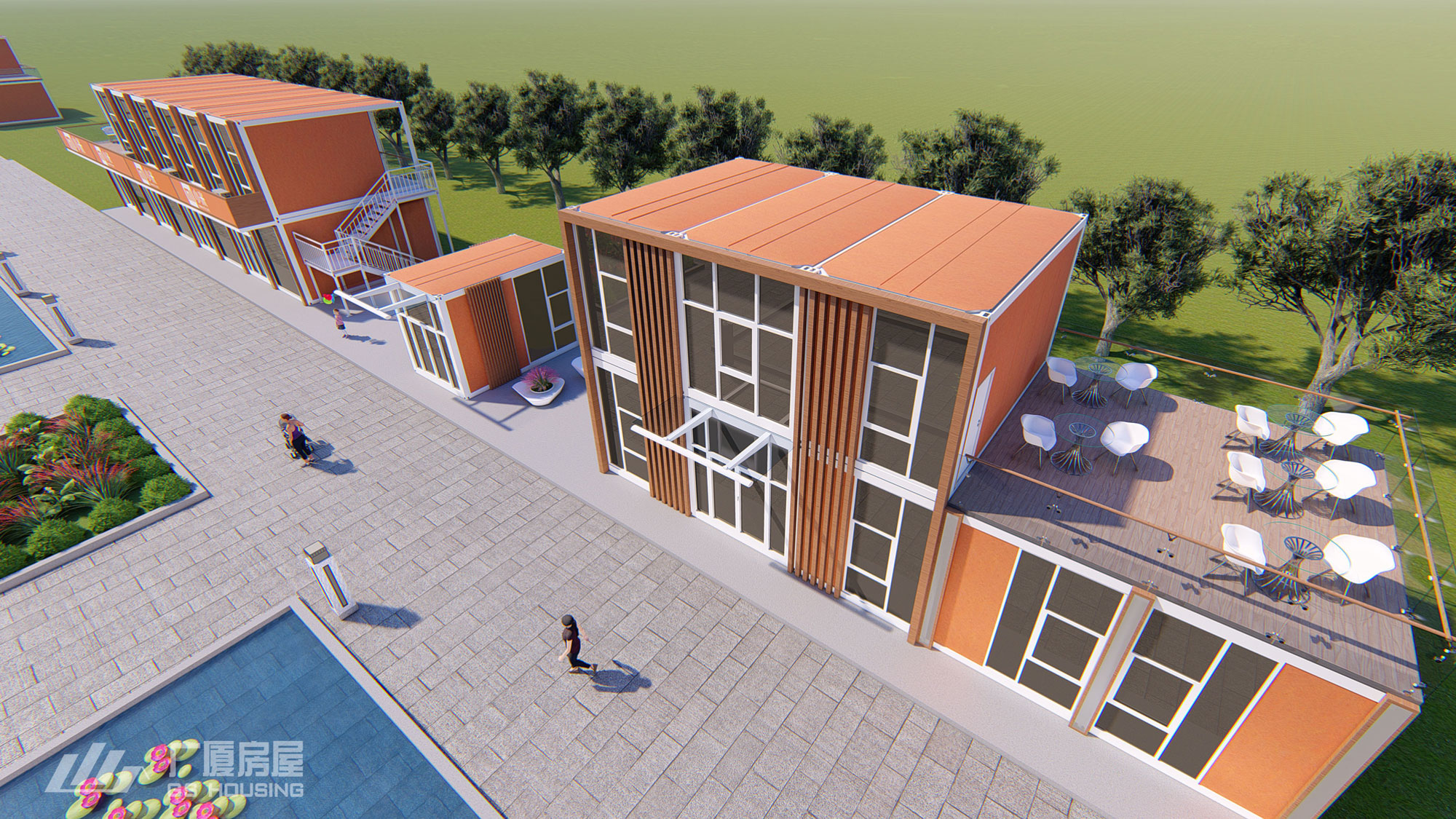

Unlike traditional shopping malls, a modular fabricated detachable fast assemble commercial street will provide flexible display space for brands and only charge low rent. Both in terms of geographical location and brand positioning, it is suitable for brands with young personalities to settle in.

There are a lot of people think that there is no way to make a higher grade of low cost modular house / prefab house / prefabricated modern flat pack container house, it is only suitable for their own entertainment. In fact, the commercial street made by modular house / prefab house / fabricated modern flat pack container house already had an embryonic form. In the International Financial Center of Chengdu, an innovative architectural complex in the shape of personalized and colorful fabricated house / modular house has been built.

It is a global creative and cultural exchange platform integrating architectural design, graphic design, cultural and creative design, industrial design. It integrates creative and cultural institutions, art galleries, independent designers, fashion trendsetter and other creative resources from the UK, Denmark, Japan, Taiwan and other parts of the world. It is divided into three functional areas: "Creative art workshop", "Public culture exhibition hall" and "urban fashion leisure area".

In addition, fabricated building and light dining are inseparable good partners, using the terrace to construct coffee, bar, gallery, restaurant, hotel situationally. . .

Restaurant

Hotel

Specialising in a wide range of custom containers, we can complete orders according to our customers' unique specifications -- we can help you assess your needs and develop the perfect modular design for your housing needs, while complying with your local building policies.

At GS Housing, we specialize in a wide range of fabricated houses ( modular building/ prefabricated building), fulfilling orders to our clients' unique specifications - we can help you assess your needs and develop the perfect modular design for your desired occupancy, while complying with your local building policies

Let’s examine the following aspects of the modular concept and development process, and consider how utilizing the fabricated building to the commercial street would make a great choice.

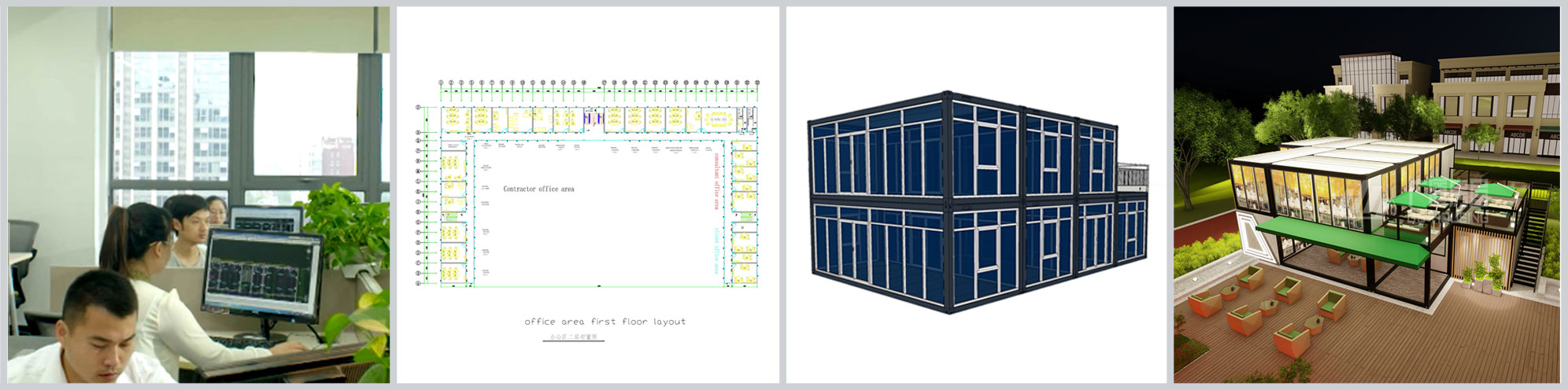

Fabricated Building / Fabricated House Design Process

The standard sizes of the standard fabricated house / fabricated building are L:6m*W3m and L:6m*W:2.4m, Height are 2.8m and 3.2m, of course the other sizes can be produced too, the modular units can be designed to be stacked on top of one another or placed side by side for additional floor space.

We’ll provide plane figures, effect drawings of the commercial fabricated house according to your perfer output and styles.

If you only have an idea of your interested houses in your mind? We also can help to make your ideal house ture.

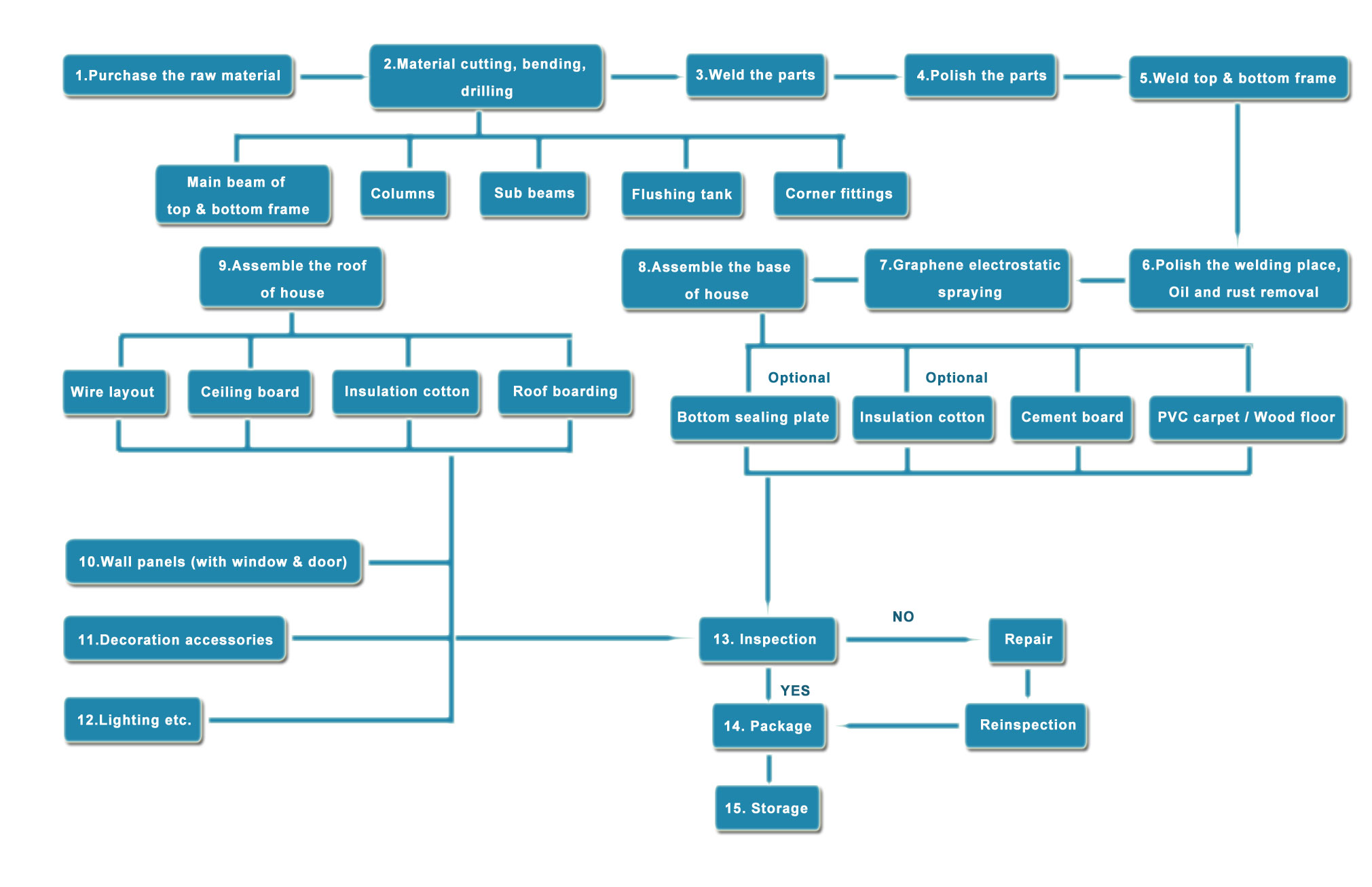

Fabricated Building / Fabricated House Production Process

Each of our fabricated house / fabricated building components is prefabricated in our factory, and there are mainly 4 parts of the fabricated house / fabricated building: Top & Bottom frames, Columns, exchangable wall panels, and decoration (include water supply and drainage system, power system...)

The following pic is more helpful for us to understand

Fabricated Building / Fabricated House Installation Process

Fabricated Building / Fabricated House Features

Industrialization

Large-scale assembly production line.

The prefab house parts are cutting and assemble with high-tech CNC technology, proves the quality of the prefabricated house, as well as saves the labor cost.

Multiple combinations

The house can be combined in various ways with a single prefabricated house as an unit, an unit can be a whole room or devided into several rooms,or formed a part of a large room, three-layer can be stacked with decorations too,such as roof and terrace.

Energy saving and Eco-friendly

The prefabricated building adopts the "factory production+ on-site installation" model, which reduces 60% construction&renovation waste,saves 50% energy,and improves 2-3 times overall production efficiency.

Safe and durable

The structure of the prefrabricated house has passed the inspection of national institutions. It can stand well after passed 8 grade earthquake ,12 grade wind, as well as the prefabricated house can be used more than 20 years.

It has the stronger anti-vibration,compression resistance, heat preservation, sound insulation, fire resistance, waterproof,snow and wind resistance than normal prefab house.

Easy to move

The Flat packed container house has good performance and can be transported by road,railway,ship and other ways. Relocation does not require demolition, and can be relocated without loss.

Wide aplications

According to different demands, the prefabricated house can be designed into functional units such as office,accommodation, foyer, bathroom,kitchen,dining room,recreation room, meeting room, clinic, laundry room,storage room, command post, etc.

| Prefabricated Modular Restaurant Diner Room, Mobile Shop, Store House specifiction | ||

| Specifiction | L*W*H(mm) | Outer size 6055*2990/2435*2896 Inner size 5845*2780/2225*2590 customzied size could be provided |

| Roof type | Flat roof with four internal drain-pipes (Drain-pipe cross size:40*80mm) | |

| Storey | ≤3 | |

| Design date | Designed service life | 20 years |

| Floor live load | 2.0KN/㎡ | |

| Roof live load | 0.5KN/㎡ | |

| Weather load | 0.6KN/㎡ | |

| Sersmic | 8 degree | |

| Structure | Column | Specification:210*150mm,Galvanized cold roll steel, t=3.0mm Material: SGC440 |

| Roof main beam | Specification:180mm,Galvanized cold roll steel, t=3.0mm Material: SGC440 | |

| Floor main beam | Specification:160mm,Galvanized cold roll steel, t=3.5mm Material: SGC440 | |

| Roof sub beam | Specification:C100*40*12*2.0*7PCS,Galvanized cold roll C steel, t=2.0mm Material:Q345B | |

| Floor sub beam | Specification:120*50*2.0*9pcs,”TT”shape pressed steel, t=2.0mm Material:Q345B | |

| Paint | Powder electrostatic spraying lacquer≥80μm | |

| Roof | Roof panel | 0.5mm Zn-Al coated colorful steel sheet, |

| Insulation material | 100mm glass wool with single Al foil. density ≥14kg/m³, Class A Non-combustible | |

| Ceiling | V-193 0.5mm pressed Zn-Al coated colorful steel sheet, hidden nail, | |

| Floor | Floor surface | 2.0mm PVC board, |

| Base | 19mm cement fiber board, density≥1.3g/cm³ | |

| Insulation(optional) | Moisture-proof plastic film | |

| Bottom sealing plate | 0.3mm Zn-Al coated board | |

| Wall | Thickness | 75mm thick colorful steel sandwich plate; Outer plate:0.5mm orange peel aluminum plated zinc colorful steel plate, ivory white, PE coating; Inner plate:0.5mm aluminum-zinc plated pure plate of color steel, white gray, PE coating; Adopt “S” type plug interface to eliminate the effect of cold and hot bridge |

| Insulation material | rock wool, density≥100kg/m³, Class A Non-combustible | |

| Door | Specification(mm) | W*H=840*2035mm |

| Material | Steel | |

| Window | Specification(mm) | Front window:W*H=1150*1100/800*1100,Back window:WXH=1150*1100/800*1100; |

| Frame material | Pastic steel, 80S, With anti-theft rod, screen window | |

| Glass | 4mm+9A+4mm double glass | |

| Electrical | Voltage | 220V~250V / 100V~130V |

| Wire | Main wire:6㎡, AC wire:4.0㎡,socket wire:2.5㎡,light switch wire:1.5㎡ | |

| Breaker | Miniature circuit breaker | |

| Lighting | Double tube lamps,30W | |

| Socket | 4pcs 5 holes socket 10A, 1pcs 3 holes AC socket 16A, 1pcs single connection plane switch 10A, (EU /US ..standard) | |

| Decoration | Top and column decorate part | 0.6mm Zn-Al coated color steel sheet, white-gray |

| Skiting | 0.6mm Zn-Al coated color steel skirting, white-grey | |

| Adopt standard construction, the equipment and fittings are accord with national standard. as well as, customized size and related facilities can be provided according to your needs. | ||

Unit House Installation Video

Stair&Corridor House Installation Video

Cobined House&External Stair Walkway Board Installataion Video