High Quality Flat Pack Shipping Container Office Manufacturers – New Portable Prefab House for Sale - Police Prefab House – GS Housing

High Quality Flat Pack Shipping Container Office Manufacturers – New Portable Prefab House for Sale - Police Prefab House – GS Housing Detail:

The police room adopts the new type of heat insulation rock wool board, the material has no formaldehyde, eco-friendly, no toxin, no peculiar smell, acid and alkali resistance, no rust, energy saving and other functions. Sound insulation, heat insulation, fireproof ,moistureproof, antifouling, easy to clean and install.

Inside of the police room can add a variety of police office facilities and living facilities,air conditions can be installed according to demand, it;s very easy to operate.

The movable office room that made by flat packed container house is the ideal place for the mobile office of public security management personnel.

Pre built homes of GS housing (mobile home manufacturers) has two standard specifications: 2.4 meters prefab house and 3 meters prefab house.

Customized service

Pre buit falt packed container house gives designers greater flexibility, can be customized according to customer requirements.the house can be assembled and combined in any length and width direction and could be stacked in three layers. Modeling roof and terrace can be decorated on the houses too.

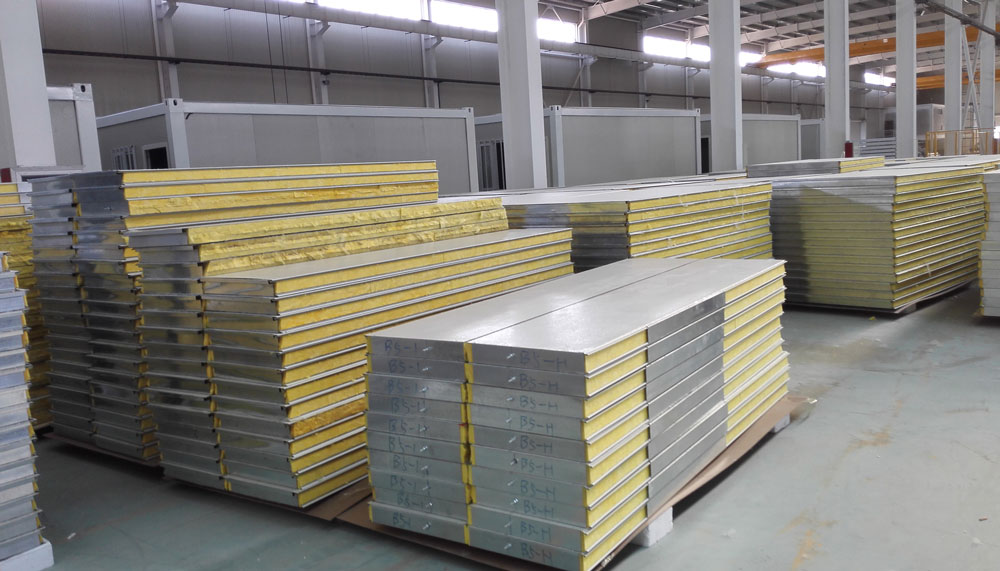

Production equipment

There’s more than 60 engineering and technical personnel, more than 600 professional technicians. The advanced modular housing production lines of GS housing(Tianjin production base)include 2 fully automatic composite board production lines, 1 electrostatic spraying production line, 1 sproctoring machine production line, 2 welding production lines, 3 light steel structure production lines, 15 continuous roller cold rolling forming equipment, the production has realized full numerical control,and equipped with radial drilling machine, CNC flame cutting machine, vertical lifting table milling machine, hydraulic sheet bending machine … more than 150 sets of auxiliary equipment, and equipped with high-quality operating technicians, to ensure that each component is perfect.

Through the fully automatic composite board production line with perfect mechanism, the production of wallboard system maintains high production efficiency, safety and environmental protection, and can reduce the generation of industrial waste to a great extent. Ensure a clean and efficient workshop environment. Meet the requirements of standardized production.

Wall panel system:

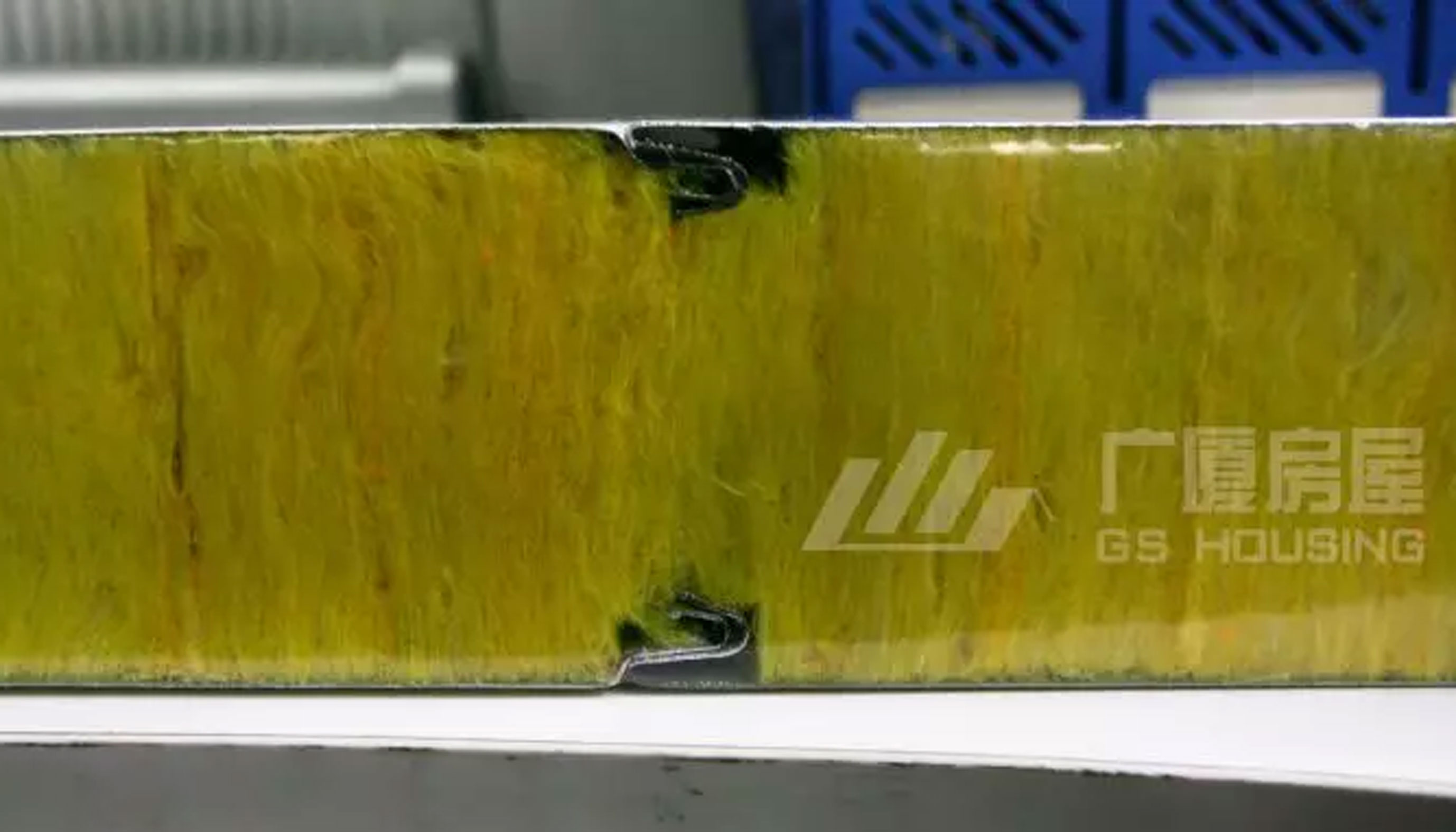

1. Wall panel plug-in button: S-shaped plug-in interface, the design could eliminate the cold and hot bridge effect and improve the performance of thermal insulation and energy saving.

2. Thickness: the wall adopts cold bridge free all cotton plug-in color steel glass wool sandwich plate, with an effective width of 1150mm. The components are connected by non-cold bridge, so that the cold bridge will not appear due to the shrinkage of core material when subjected to vibration and impact, so as to avoid the cold bridge on the upper part of the component after the bulk thermal insulation material is subjected to earthquake.

Whether in high or low temperature environment, the thermal insulation cotton can maintain good thermal insulation performance. It has the characteristics of non combustion, non toxicity, low thermal conductivity, good sound absorption performance, good insulation, chemical stability, long service life and so on.

3. Outer plate: 0.5mm orange peel aluminum zinc plated color steel plate, PE coating, aluminum zinc content ≥ 40g / ㎡

4. Insulation layer: 64kg / M ³ Glass wool, combustion performance class A, non combustible.

5. Inner plate: 0.5mm aluminum zinc plated color steel pure plate, PE coating, aluminum zinc content ≥ 40g / ㎡.

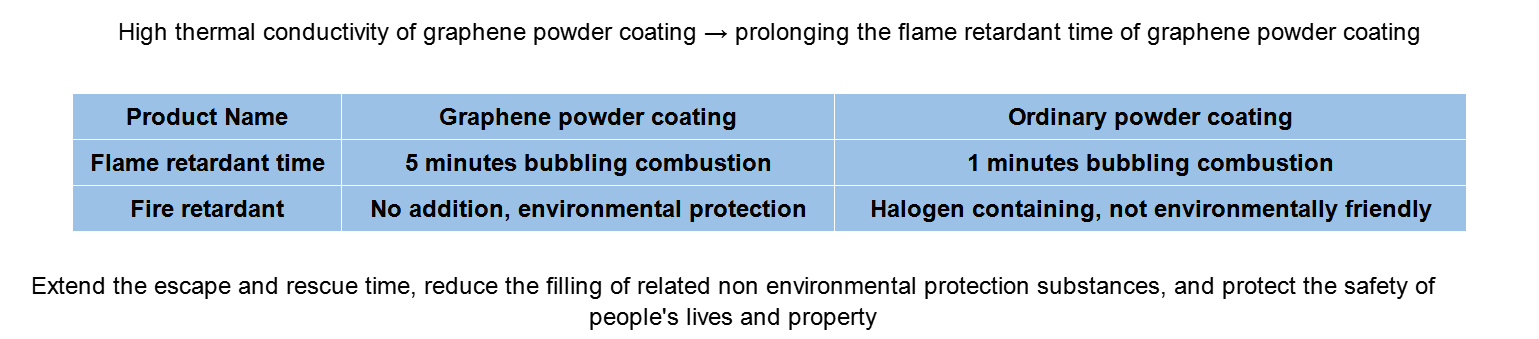

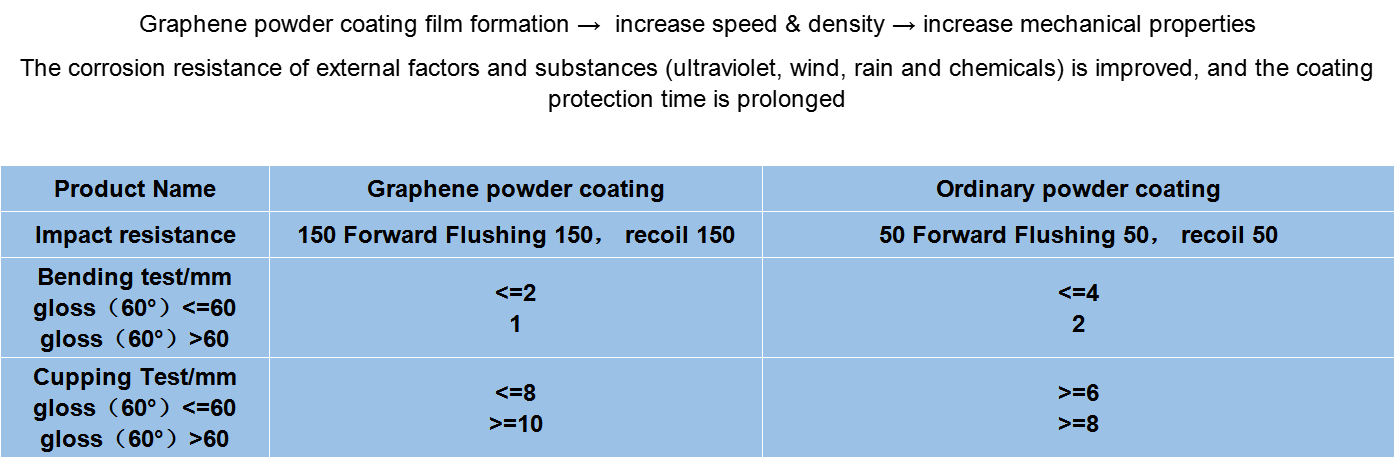

Graphene spraying

1. Best conductivity – graphene is the material with the lowest resistivity in the world, only about 10-8Ωm. Lower resistivity than copper and silver. At the same time, the electron mobility at room temperature is as high as 1500cm2/v.s, which exceeds that of brick and carbon tube. The current density tolerance is the largest, it is expected to reach 200 million a/cm2.

2. The heat dissipation is the best – the thermal conductivity of single-layer graphene is 5300w / m.k, which is higher than that of carbon nanotubes and diamond.

3. Excellent corrosion and weather resistance.

4. Super toughness – the failure strength is 42N/m, the young’s modulus is equivalent to that of diamond, the strength is 100 times that of high-quality steel, and has excellent flexibility.

5. Special structure and excellent ductility. Ultra light and thin, with a maximum thickness of 0.34nm and a specific surface area of 2630 m2/g.

6. Transparency – graphene is almost completely transparent and absorbs only 2.3% of light.

Graphene powder coating has ultra-high thermal conductivity, improves the corrosion resistance of external factors and substances (UV, wind, rain and chemicals) (up to 20 years), and prolongs the flame retardant time and service life of the coating; Beautiful appearance, bright and rich colors, improve the protection strength, and reduce the construction environment and technical requirements. Because of its special nanostructure and excellent physical and chemical properties, it is recognized as the “future material” and “revolutionary material” in the 21st century.

Comparison between traditional painting and graphene powder electrostatic spraying.

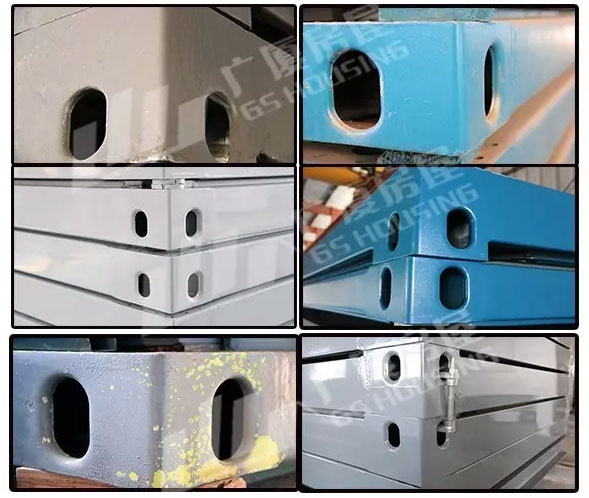

Product detail pictures:

Related Product Guide:

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for High Quality Flat Pack Shipping Container Office Manufacturers – New Portable Prefab House for Sale - Police Prefab House – GS Housing , The product will supply to all over the world, such as: Brasilia, Vietnam, Gambia, Besides there are also professional production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable products quality, increase customers' satisfaction and achieve win-win situation .

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.