GS Housing Customized Flat Pack Housing with Glass Window

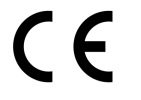

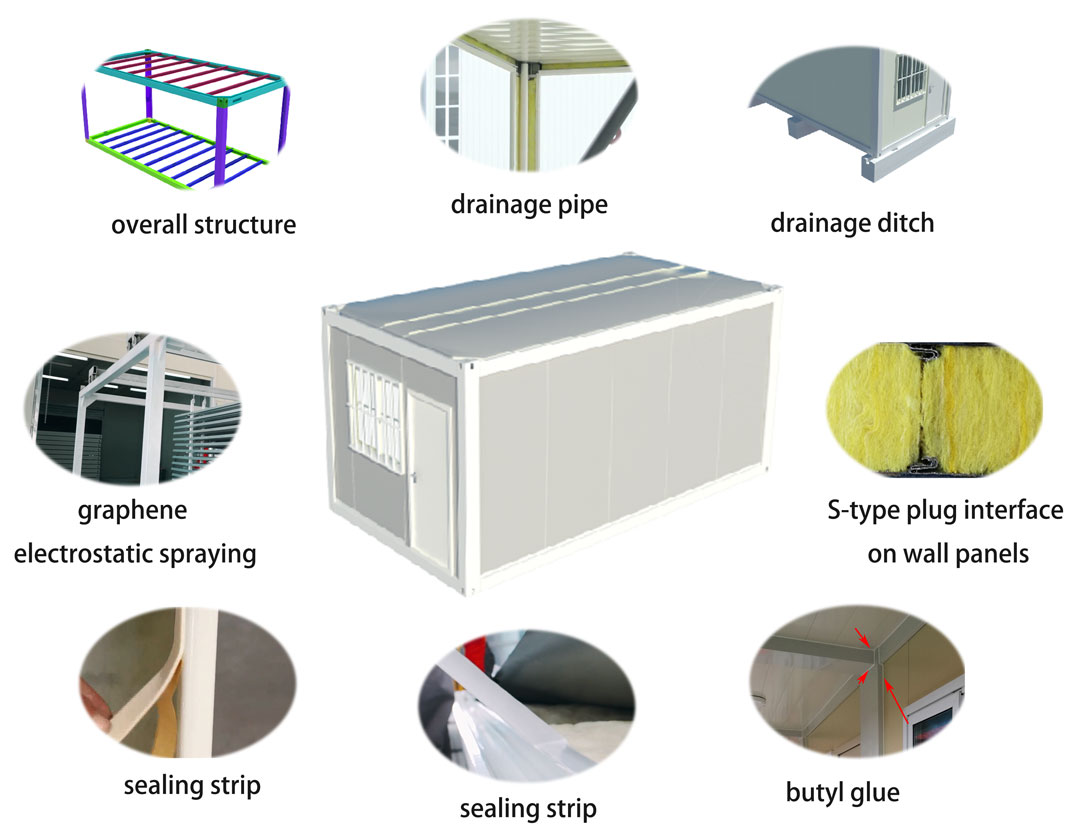

Structure of the flat pack cabin homes

The flat packed housing is composed of top frame components, bottom frame components, columns and several interchangeable wall panels. Using modular design concepts and production technology, modularize a house into standard parts and assemble the house on the construction site.

Bottom Frame System of Affordable Flat Pack Homes

Main beam:3.5mm SGC340 galvanized cold-rolled steel profile; more thicker than top frame main beam

Sub-beam:9pcs "π" typed Q345B, spec.:120*2.0

Bottom sealing plate:0.3mm steel

Cement fiber board:20mm thick, green and environmental protection, density ≥1.5g/cm³, A-grade non-combustible.Compared with the traditional glass magnesium board and Osong board, the cement fiber board is more strenger and does not deform when exposed to water.

PVC floor:2.0mm thick, B1 class flame retardant

Insulation(optional):Moisture-proof plastic film

Base External Plate:0.3mm Zn-Al coated board

Top Frame System of Flat Pack Cabin Homes

Main beam:3.0mm SGC340 galvanized cold-rolled steel profile

Sub-beam: 7pcs Q345B galvanizing steel, spec. C100x40x12x1.5mm, the space between sub-beams is 755m

Drainage :4pcs 77x42mm, connected with four 50mm PVC downspouts

Outer roof panel:0.5mm thick aluminum zinc color steel plate, PE coating, aluminum zinc content ≥40g/㎡. Strong anticorrosion, 20 years guaranteed life

Self - locking ceiling plate:0.5mm thick aluminum-zinc color steel plate, PE coating, aluminum-zinc content ≥40g/㎡

Insulation layer:100mm thick glass fiber wool felt with aluminum foil on one side, bulk density ≥14kg/m³, class A non-combustible

Corner Post&Column System of flat pack modular house

Corner column: 4pcs,3.0mm SGC440 galvanized cold rolled steel profile,the columns are connected with top & bottom frame with Hexagon head bolts (strength: 8.8),the insulation block should be filled in after installed columns

Corner post: 4mm thick square pass, 210mm*150mm, integral molding. Welding method: Robot welding, precise and efficient. Galvanized after pickling to increase paint adhesion and prevent rust

Insulating tapes: among the junctions of the corner post and the wall panels to prevent the effect of cold and heat bridges and improve the performance of heat preservation and energy saving

Wall Panel of Flat Pack Portable Buildings

Outer board: 0.5mm thick galvanized color steel plate, aluminum plated The zinc content is ≥40g/㎡, which guarantees anti-fading and anti-rust for 20 years

Insulation layer: 50-120mm thick hydrophobic basalt wool (environmental protection), density ≥100kg/m³, class A non-combustible Inner board: 0.5mm Alu-zinc colorful steel plate, PE coating

Binding: The upper and lower ends of the wall panels are sealed with galvanized edging (0.6mm galvanized sheet).There are 2 M8 screws embedded in the top, which are locked and fixed with the groove of the main beam through the side plate pressing piece

| Model | Spec. | House outer size(mm) | House inner size (mm) | Weight(KG) | |||||

| L | W | H/packed | H/assembled | L | W | H/assembled | |||

| Type G

Flat packed housing |

2435mm standard house | 6055 | 2435 | 660 | 2896 | 5845 | 2225 | 2590 | 2060 |

| 2990mm standard house | 6055 | 2990 | 660 | 2896 | 5845 | 2780 | 2590 | 2145 | |

| 2435mm corridor house | 5995 | 2435 | 380 | 2896 | 5785 | 2225 | 2590 | 1960 | |

| 1930mm corridor house | 6055 | 1930 | 380 | 2896 | 5785 | 1720 | 2590 | 1835 | |

2435mm standard house

2990mm standard house

2435mm corridor house

1930mm corridor house

Certification of the flat pack container homes

ASTM CERTIFICATION

CE CERTIFICATION

SGS CERTIFICATION

EAC CERTIFICATION

Features of GS housing flat pack prefab

❈ Good drainage performance

Drainage ditch:Four PVC downpipes with a diameter of 50mm are connected inside the top frame assembly to meet the drainage needs. Calculated according to the heavy rain level (250mm precipitation), the sinking time is 19min, the top frame sinking speed is 0.05L/S. The drainage pipe displacement is 3.76L/S, and the drainage speed is much higher than the sinking speed.

❈ Good sealing performance

Top frame sealing treatment of unit house: 360-degree lap joint outer roof panel to prevent rainwater from entering the room from the roof. The joints of doors / windows and wall panels are sealed with sealant top frame sealing treatment of combined houses: sealing with sealing strip and butyl glue, and decorating with steel decoration fiting . column sealing treatment of combined houses:sealing with sealing strip and decorating with steel decoration fiting . S-type plug interface on wall panels to enhance the sealing performance.

❈ Anti-corrosion performance

GS housing group is the first manufacturer to apply graphene electrostatic spraying process to flat packed container house. The polished structural parts enter the spraying workshop, and the powder is evenly sprayed on the surface of the structure. After heating at 200 degrees for 1 hour, the powder is melted and attached to the surface of the structure. The spray shop can accommodate 19 sets of top frame or bottom frame processing at a time. Preservative can last up to 20 years.

Supporting facilities of insulated flat pack container

Complete supporting facilities

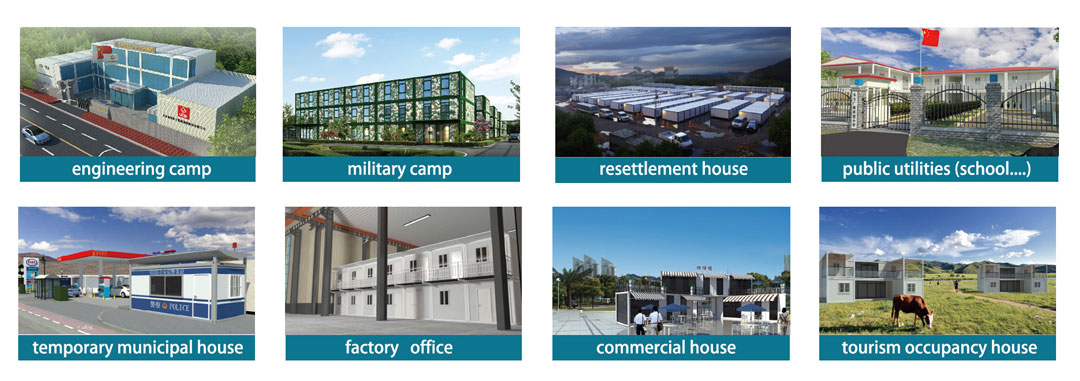

Application scenario of flat pack accommodation

Flat pack building can be designed to engineering camp, military camp, resettlement house, schools, mining camp, commercial house(coffee, hall), tourism occupancy house (beach, grassland) and so on.

R&D dept. of GS Housing Group

The R&D company is responsible for various design-related work of the GS Housing group, including new product development, product upgrade, scheme design, construction drawing design, budget, technical guidance, etc.

Continuous improvement and innovation in the promotion and application of prefabricated buildings, to meet the diversified requirements of different customers in the market, and to ensure the continuous competitiveness of the GS housing's products in the market.

Installation team of GS Housing Group

Xiamen GS Housing Construction Labor Service Co., Ltd. is a professional installation engineering company under GS Housing Group. which mainly engaged in the installation, dismantling, repair and maintenance of prefabricated K & KZ & T house and container houses, there are seven installation service centers in East China, South China, West China, North China, Central China, Northeast China and International, with more than 560 professional installation workers, and we has successfully delivered more than 3000 engineering projects to customers.

Flat pack builder- GS housing group

GS Housing group was established in 2001 withintegrating prefabricated building design, production, sales and construction.

GS housing group owns Beijing (Tianjin production base), Jiangsu (Changshu production base),Guangdong(Foshan production base), Sichuan (Ziyang production base), Liaozhong (Shenyang production base), International and Supply Chain Companines.

GS housing group is committed to the R&D and production of the prefabricated buildings: flat packed container houses, prefab KZ house, prefeb K&T house, steel structure, which are widely used in various scenarios, such as engineering camps, military camps,temporary municipal houses,tourism and vacation, commercial houses, education houses, and resettlement houses in disaster areas...