Good Price Sandwich Panel Light Steel Prefabricated Prefab Houses for Sale

Background of the Sandwich Panel Prefabricated Houses

The Bolivia La Paz Water Supply Project Department's camp and "employee home" were fully completed and put into use.

The camp covers an area of about 10,641 square meters made by prefab KT house, including five areas: office, laboratory, dormitory, canteen, and parking lot. The green area of the camp is 2,500 square meters, and the greening rate is as high as 50%.

The dormitory area has a total area of 1025 square meters, including 50 rooms, which can accommodate 128 people, and the per capita construction area is 8 square meters. There is a communal laundry room and 4 bathrooms for men and women. There are 2 canteens and kitchens, which are divided into Chinese staff canteens and local staff canteens, and are equipped with heat preservation dining tables, disinfection cabinets, coffee machines and other facilities.

Because the project camp is located on a plateau, the infirmary of the project department is equipped with oxygen tubes, medicine boxes, hospital beds, medicines and facilities to relieve altitude sickness, so as to meet the basic medical treatment of project employees. In accordance with the construction requirements of the "Workers' Home", the project is also divided into cultural and sports areas, including a series of supporting facilities such as basketball, football, table tennis, billiards, and KTV.

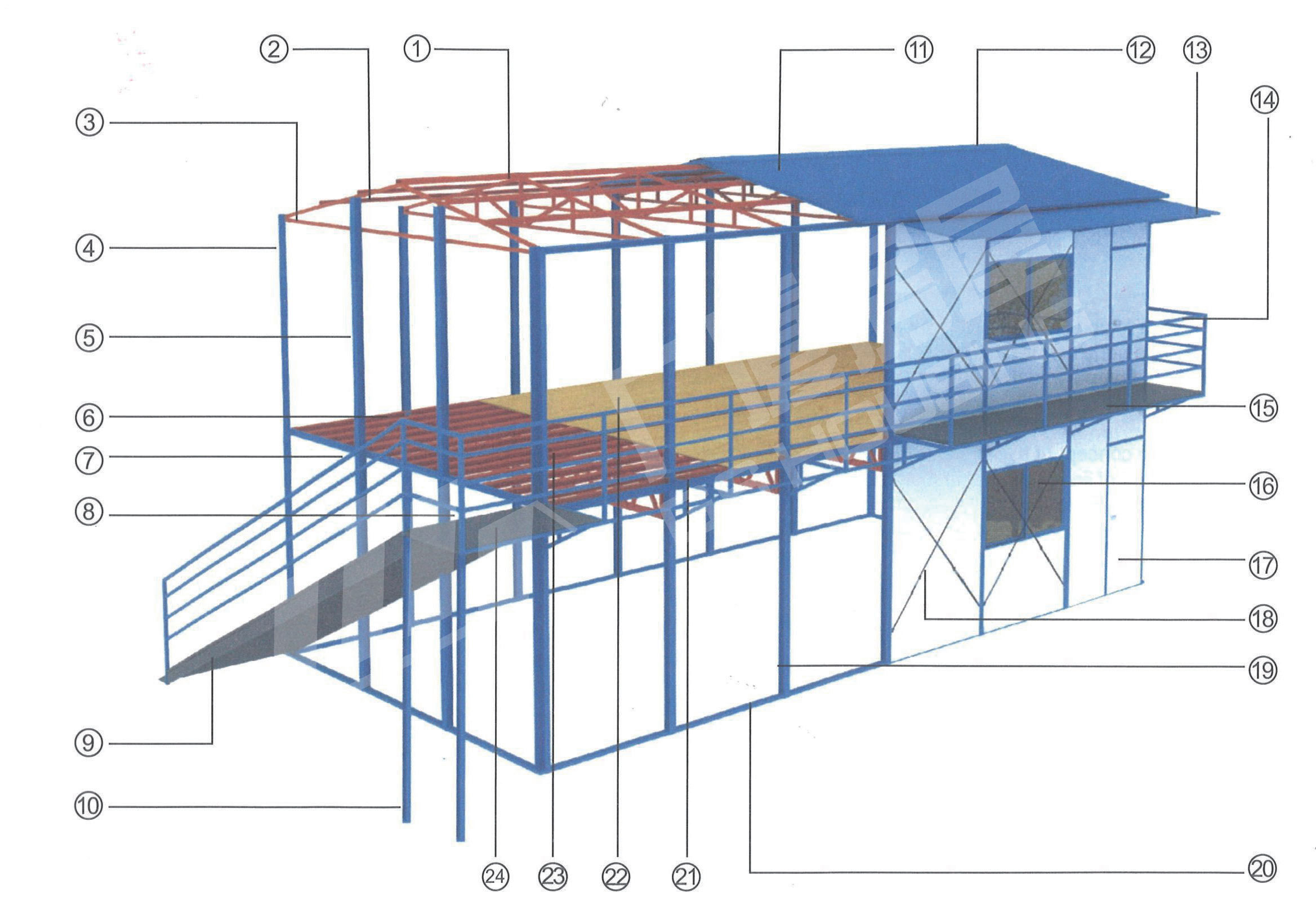

Technical Parameters of Sandwich Panel Prefabricated Houses

①roof frame ②roof purlin ③ring beam ④corner post ⑤cable post ⑥floor purlin ⑦stair rail ⑧handrail ⑨staircase ⑩walk way bracket post ⑪roof panel ⑫ridge tile ⑬canopy ⑭handrail ⑮walkway floor board ⑯Alu sliding window ⑰composite door ⑱cross bar ⑲central post ⑳ground joist ㉑walkway supporting beam ㉒floor board ㉓floor beam ㉔walkway bracket

1. The building safety level is level III.

2. Basic wind pressure: 0.45kn/m2, ground roughness class B

3. Seismic fortification intensity: 8 degrees

4. Roof dead load: 0.2 kn/㎡, live load: 0.30 kn/㎡; Floor dead load: 0.2 kn/㎡, live load: 1.5 kn/㎡

Features of Sandwich Panel Prefabricated Houses

1. Reliable structure: light steel flexible structure system, safe and reliable, meeting the requirements of building structure design code.

2. The product can withstand wind of Grade 10 and seismic intensity of Grade 7;

3. Convenient dis-assembly and assembly: the house can be disassembled and reused for many times.

4. Beautiful decoration: the house is beautiful and generous as a whole, bright color, flat board surface and good decorative effect.

5. Structural waterproof: the house adopts structural waterproof design without any additional waterproof treatment.

6. Long service life: light steel structures are treated with anti-corrosion spraying, and the normal service life can reach more than 10 years.

7. Environmental protection and economy: the house has reasonable design, simple dis-assembly and assembly, can be recycled for many times, low loss rate and no construction waste.

8. Sealing effect: the house has the effects of tight sealing, heat insulation, waterproof, fire resistance and moisture-proof.

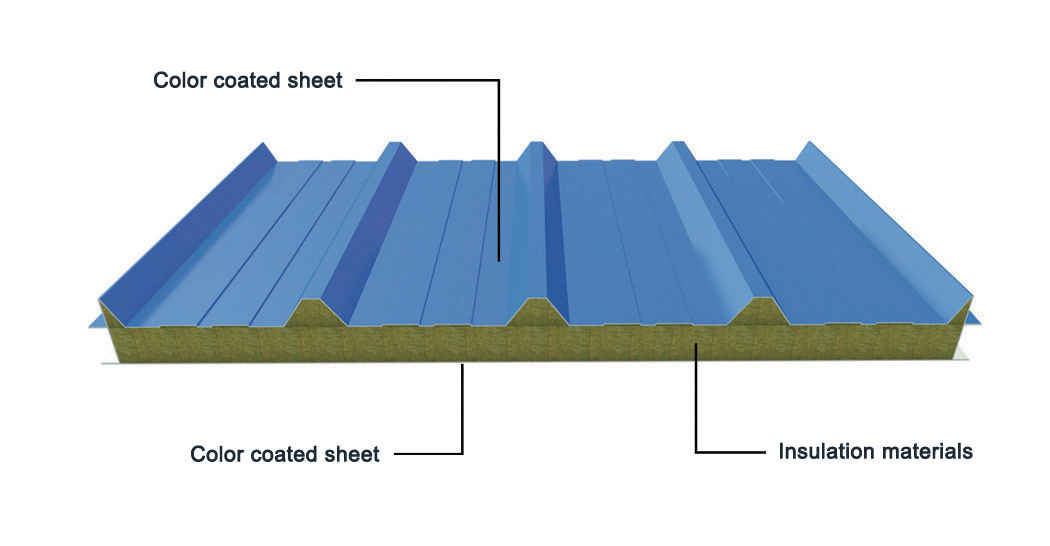

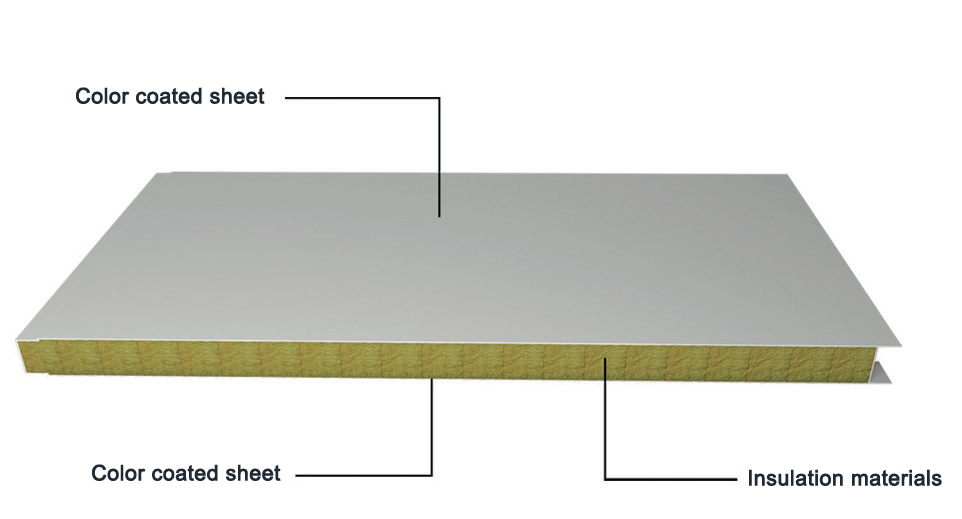

Enclosure Material of Sandwich Panel Prefabricated Houses

A. Glass wool roof panel

B.Glass wool sandwich panel

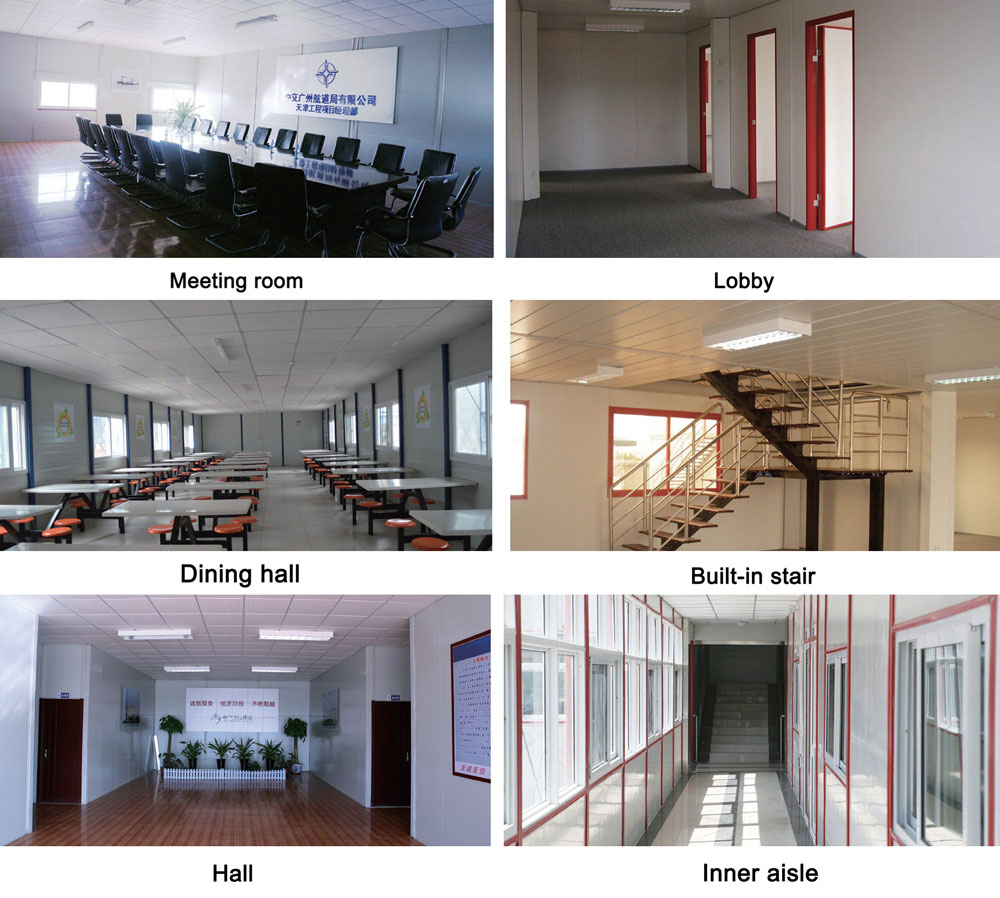

Interior Decoration

Production base of Sandwich Panel Prefabricated Houses

GS Housing's five production bases have a comprehensive annual production capacity of more than 170,000 houses,the strong comprehensive production and operation capabilities provide a solid backing for houses production.

Tianjin Factory

Jiangsu Factory

Guangdong Factory

Chengdu Factory

Shenyang Factory

Each of GS Housing production bases has the advanced supporting modular housing production lines, professional operators are equipped in each machine, so the houses can achieved the full CNC production,that ensure the houses produced timely,efficiently and accurately.