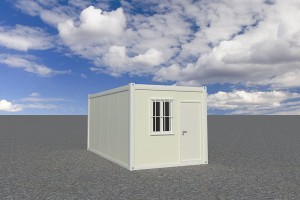

Covid-19 Emergency Modular Hospital & Inspection Container House

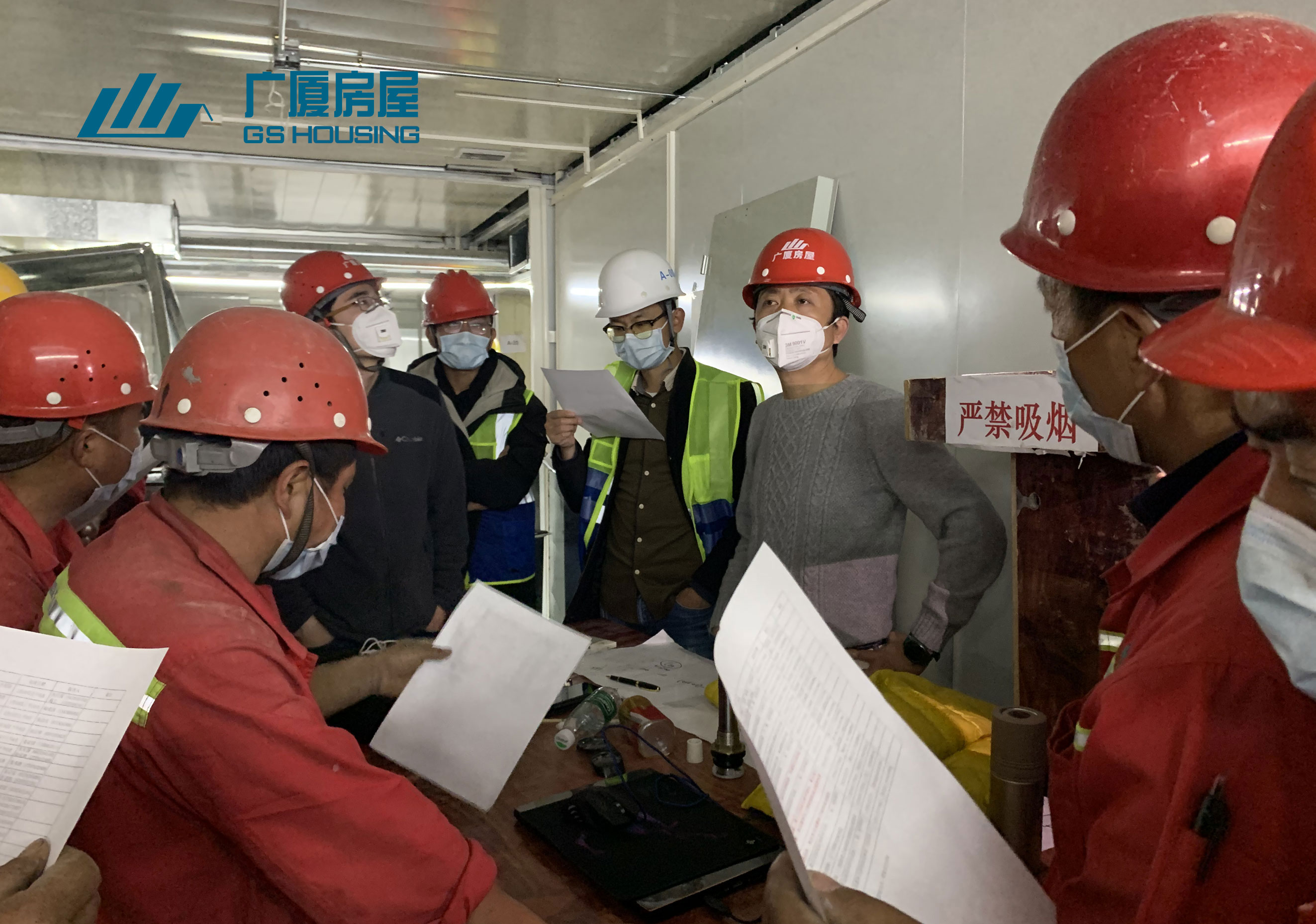

In order to cope with the COVID-19 outbreak and enhance the capacity to control the epidemic, GS Housing has been taking action. Designed the modular house suitable for Covid-19 inspection houses and the houses suitable for modular hospital, In 2020 year, the nucleic acid testing sampling contracted by GS Housing prefab house has been officially put into use. The prefab house provide a warm place for health care workers who have been fighting on the front lines of the epidemic during the cold spell.

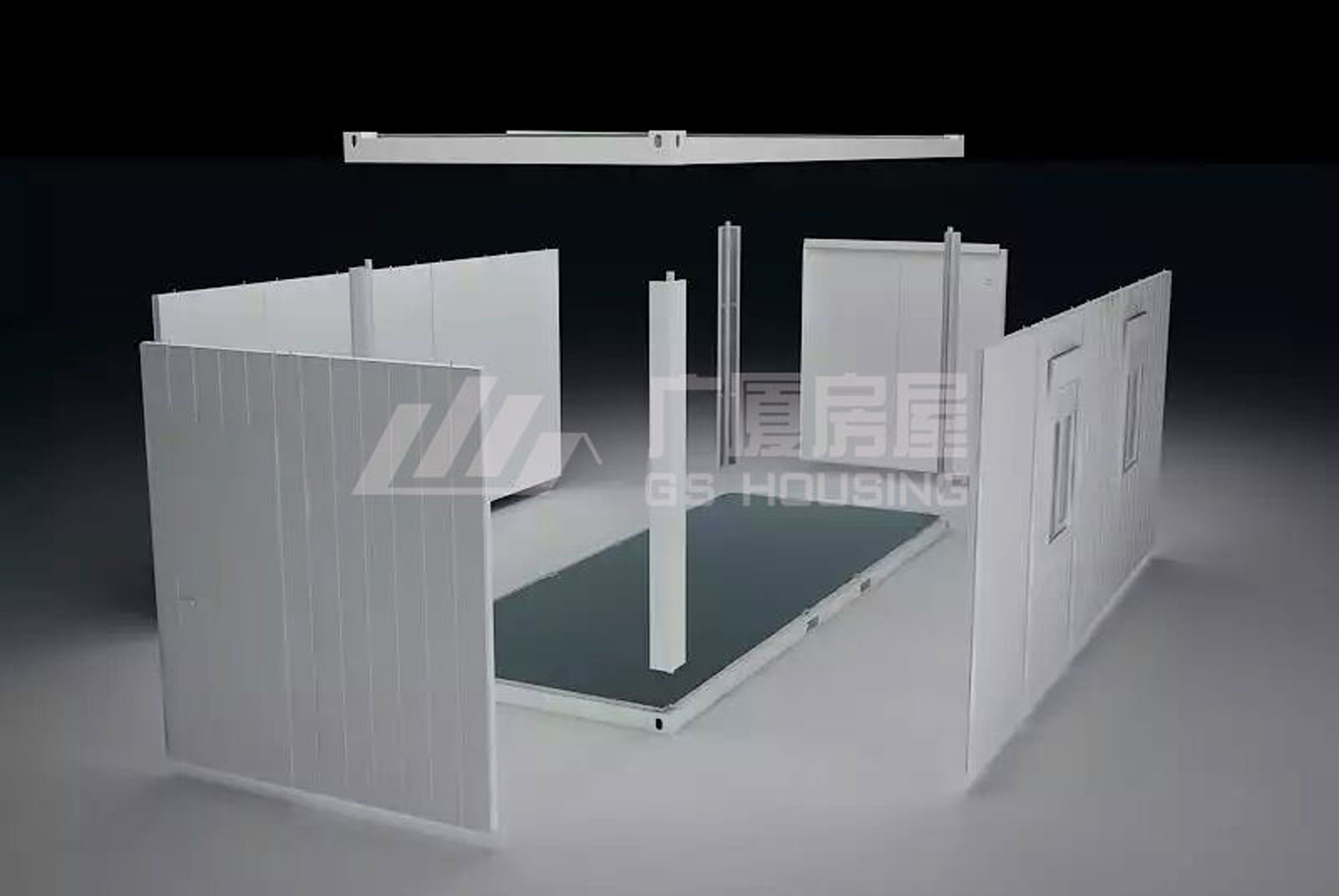

The epidemic is spreading in many countries from 2020 year, it's putting prevention and control work to the test. The large-scale production line is adopted to produce the flat packed container houses with short manufacturing cycle and strong emergency capacity.

The production capacity of our four major domestic prefab house production bases is about 400 sets modular house per day, which can meet the emergency usage.

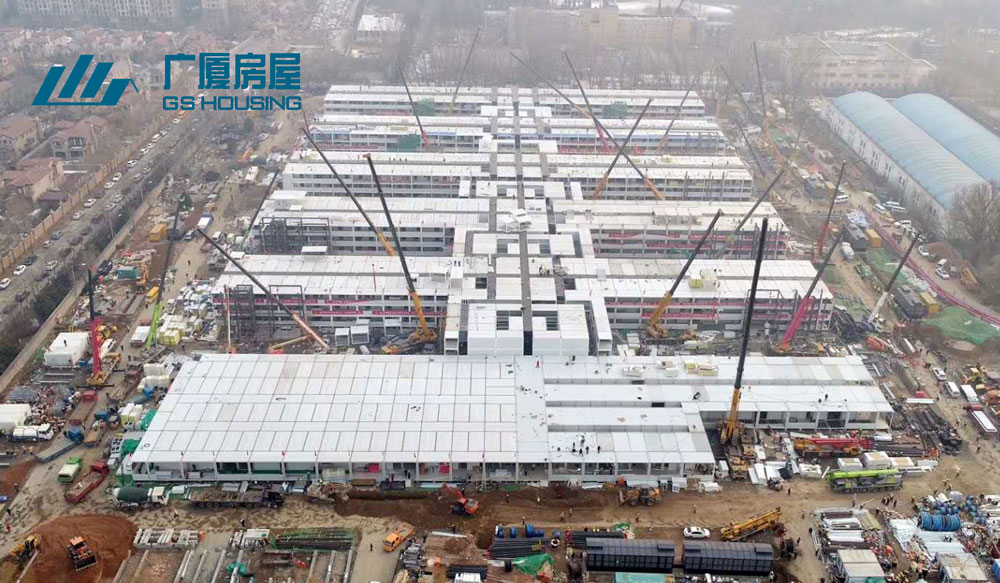

This kind flat packed container house has been widly used in various modular hospitals, such as Huoshenshan, Leishenshan makeshift hospital, HK Tsingyi modular hospital, Macao modular hospital, Xingtai modular hospital, Foshan and Shaoxing modular hospital, totally 7 modular hospitals.

Huoshenshan modular hospital

Mocao modular hospital

Leishenshan modular hospital

Foshan modular hospital

HK Tsingyi modular hospital

Shaoxing modular hospital

The Advantages to Choose Modular Hospital

Speed — Modules can be manufactured in the plant while the site is being prepared (e.g. clearing, excavating, grading, and foundation work). This overlap in processes can shave weeks or even months off your construction schedule!

Quality — Manufacturing in a factory typically results in greater precision compared to construction in the field. This is especially important for complex, high tech buildings, such as hospitals. After inspections at the factory, modules can be delivered to the site almost completely finished. This means that damage (e.g. to plumbing fixtures, medical equipment, and paintwork) is less likely.

Less waste, greater efficiency — Designing for factory manufacturing leads to less wasted material than on-site construction. Workers are also more efficient because the equipment needed for each task can be kept at each workstation on the factory line. In contrast, on a building site, workers need to walk to find tools and bring them to all the different points they work on in the building.

Less labor — Factories are designed for efficiency and require less labor than conventional construction to build an equivalent structure. This is important given the current shortage of skilled tradespeople.

No weather delays — Delays are standard for conventional construction. When a hospital is built in a factory, there are no weather delays. This can make a huge difference, especially in areas with a short construction season, or with unpredictable weather.

Cost certainty — All the materials for prefabrication are ordered up-front and stored in the factory, ready to use. This means the exact price for materials can be known right away, rather than estimating the price for materials weeks or months in the future when a conventionally built structure is ready to have them delivered to the site.

Repeatable design — If all your patient rooms are the same, the efficiencies of repeatable processes in the factory are a particularly good fit for your project.

Customizable — Prefab doesn’t mean cookie-cutter though. Just as with conventional construction, the designs for modular healthcare facilities can be adapted to your needs.

| Modular hospital specifiction | ||

| Specifiction | L*W*H(mm) | Outer size 6055*2990/2435*2896 Inner size 5845*2780/2225*2590 customzied size could be provided |

| Roof type | Flat roof with four internal drain-pipes (Drain-pipe cross size:40*80mm) | |

| Storey | ≤3 | |

| Design date | Designed service life | 20 years |

| Floor live load | 2.0KN/㎡ | |

| Roof live load | 0.5KN/㎡ | |

| Weather load | 0.6KN/㎡ | |

| Sersmic | 8 degree | |

| Structure | Column | Specification:210*150mm,Galvanized cold roll steel, t=3.0mm Material: SGC440 |

| Roof main beam | Specification:180mm,Galvanized cold roll steel, t=3.0mm Material: SGC440 | |

| Floor main beam | Specification:160mm,Galvanized cold roll steel, t=3.5mm Material: SGC440 | |

| Roof sub beam | Specification:C100*40*12*2.0*7PCS,Galvanized cold roll C steel, t=2.0mm Material:Q345B | |

| Floor sub beam | Specification:120*50*2.0*9pcs,”TT”shape pressed steel, t=2.0mm Material:Q345B | |

| Paint | Powder electrostatic spraying lacquer≥80μm | |

| Roof | Roof panel | 0.5mm Zn-Al coated colorful steel sheet, white-gray |

| Insulation material | 100mm glass wool with single Al foil. density ≥14kg/m³, Class A Non-combustible | |

| Ceiling | V-193 0.5mm pressed Zn-Al coated colorful steel sheet, hidden nail, white-gray | |

| Floor | Floor surface | 2.0mm PVC board, light gray |

| Base | 19mm cement fiber board, density≥1.3g/cm³ | |

| Insulation(optional) | Moisture-proof plastic film | |

| Bottom sealing plate | 0.3mm Zn-Al coated board | |

| Wall | Thickness | 75mm thick colorful steel sandwich plate; Outer plate:0.5mm orange peel aluminum plated zinc colorful steel plate, ivory white, PE coating; Inner plate:0.5mm aluminum-zinc plated pure plate of color steel, white gray, PE coating; Adopt “S” type plug interface to eliminate the effect of cold and hot bridge |

| Insulation material | rock wool, density≥100kg/m³, Class A Non-combustible | |

| Door | Specification(mm) | W*H=840*2035mm |

| Material | Steel | |

| Window | Specification(mm) | Front window:W*H=1150*1100/800*1100,Back window:WXH=1150*1100/800*1100; |

| Frame material | Pastic steel, 80S, With anti-theft rod, screen window | |

| Glass | 4mm+9A+4mm double glass | |

| Electrical | Voltage | 220V~250V / 100V~130V |

| Wire | Main wire:6㎡, AC wire:4.0㎡,socket wire:2.5㎡,light switch wire:1.5㎡ | |

| Breaker | Miniature circuit breaker | |

| Lighting | Double tube lamps,30W | |

| Socket | 4pcs 5 holes socket 10A, 1pcs 3 holes AC socket 16A, 1pcs single connection plane switch 10A, (EU /US ..standard) | |

| Decoration | Top and column decorate part | 0.6mm Zn-Al coated color steel sheet, white-gray |

| Skiting | 0.6mm Zn-Al coated color steel skirting, white-grey | |

| Adopt standard construction, the equipment and fittings are accord with national standard. as well as, customized size and related facilities can be provided according to your needs. | ||