Buy Best Container Van House Suppliers – New Design Laundry Modular House – GS Housing

Buy Best Container Van House Suppliers – New Design Laundry Modular House – GS Housing Detail:

How About The Inner of The Launday Modular Homes?

Now, let’s see the laundry modular home picture:

1.The washing machine specification, quantity can be customized according to difference camp requirements. Our professional designers will provide the suitable plan according to the camp design, the number of staff, different usage environment….

2.Clothes dryers,shoe washing machine, vending machine, wash basin….can be added in the laundry modular room to meet the needs of different people.

3.We design the rest table and chairs for people when waiting for washing clothes, as well as built a place for people gossip.

4.The broken bridge aluminum door and window that used on the laundry modular house makes the modular home looks more luxurious, and good for air circulation.

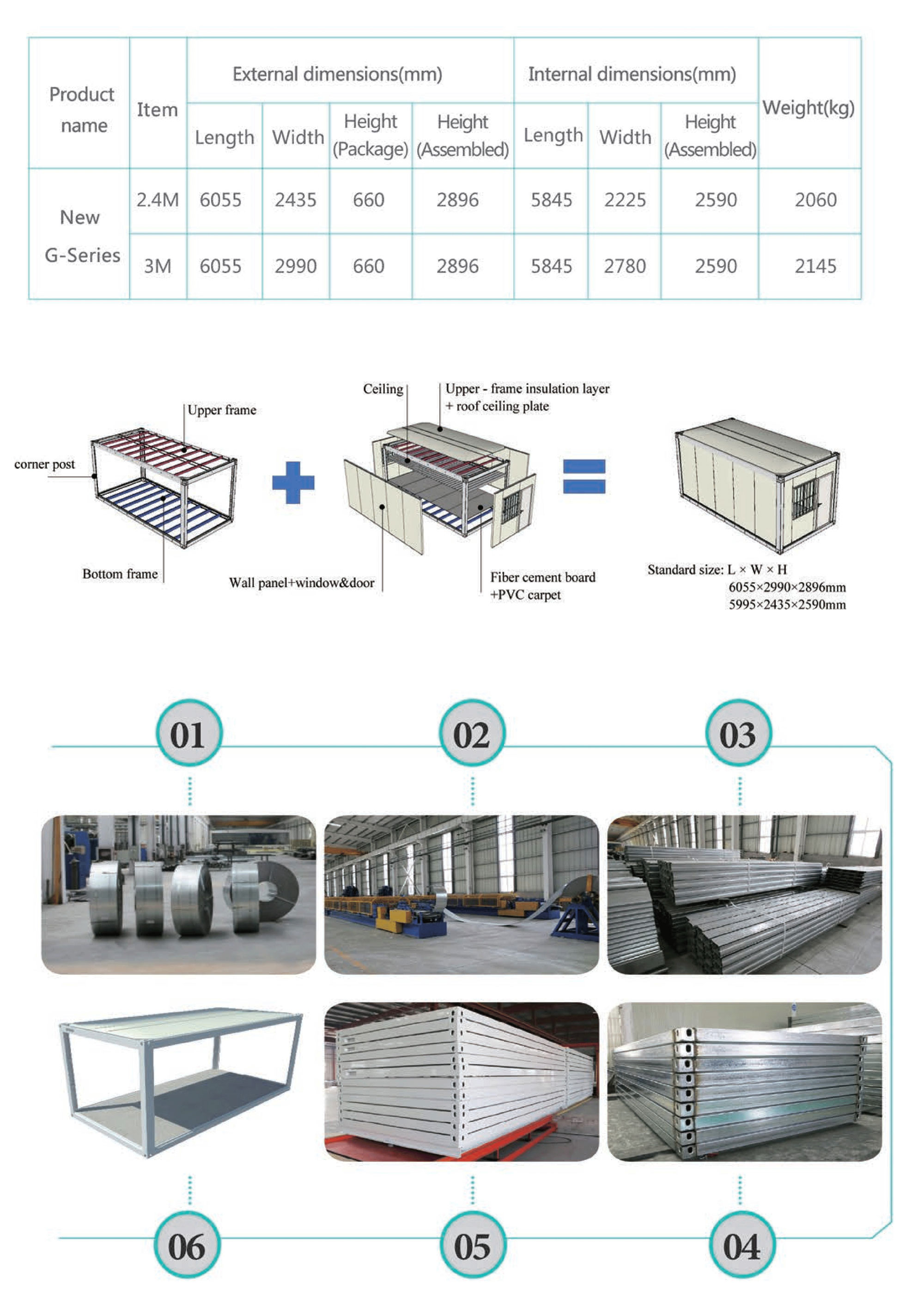

The Produce Process of The Container Home

3 meter width container house and 2.4 meter width container house are our standard size container house, of course, other size can be done too, if you need the customized size, or if you only have an ideas of the whole house, welcome to mail us to get the detail design plan.

The raw materials of GS housing prefab house (galvanized steel) are rolled into top frame beam/bottom frame beam/corner column by rolling molding machine through computer programming, and then assembled into top frame and bottom frame after grinding and welding. (galvanized component: galvanized layer thickness ≥10μm, zinc content ≥90 g /㎡).

The corner columns and structure surface of the container house are coated with graphene electrostatic powder spraying technology to ensure that the color will not fade for 20 years. Graphene is a new material consisting of a single sheet structure of carbon atoms connected by a hexagonal grid. It is the most ductile and strongest nanomaterial found so far. Because of its special nano structure and excellent physical and chemical properties, it is recognized as the “future material” and “revolutionary material” in the 21st century.

Product detail pictures:

Related Product Guide:

Our corporation puts emphasis about the administration, the introduction of talented staff, plus the construction of team building, attempting hard to improve the quality and liability consciousness of team members. Our organization successfully attained IS9001 Certification and European CE Certification of Buy Best Container Van House Suppliers – New Design Laundry Modular House – GS Housing , The product will supply to all over the world, such as: Melbourne, Estonia, Gabon, With the advanced workshop, professional design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our products are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.