The Manufacturer of Steel Structure Building Factory

Steel structure is a metal structure fabricated with steel for the internal support and other materials for exterior cladding,e.g. floors, walls... As well as the steel structure building can also be divided into light steel structure and heavy steel structure building according to it’s overall size.

Which kind steel is suitable for your need building? Contact us for the suitable design plan.

Steel fabricated buildings are used for a variety of purposes including storage, work spaces and living accommodation. They are classified into specific types depending on how they are used.

Main Structure of The Steel Structure House

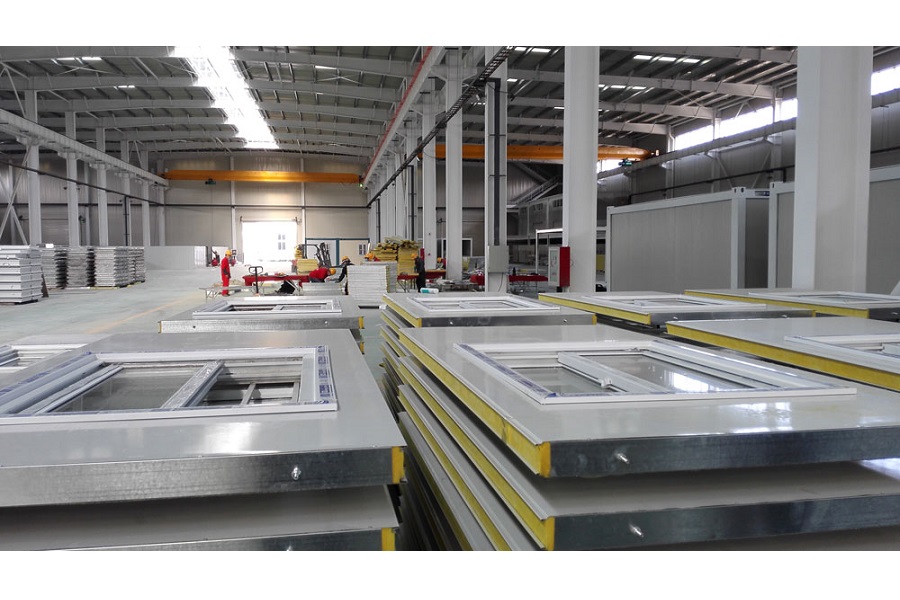

The Wall Panel: 8 Kinds of Wall Panels Could Be Chosen In Your Projects

Steel Structure Building Features

Low Cost

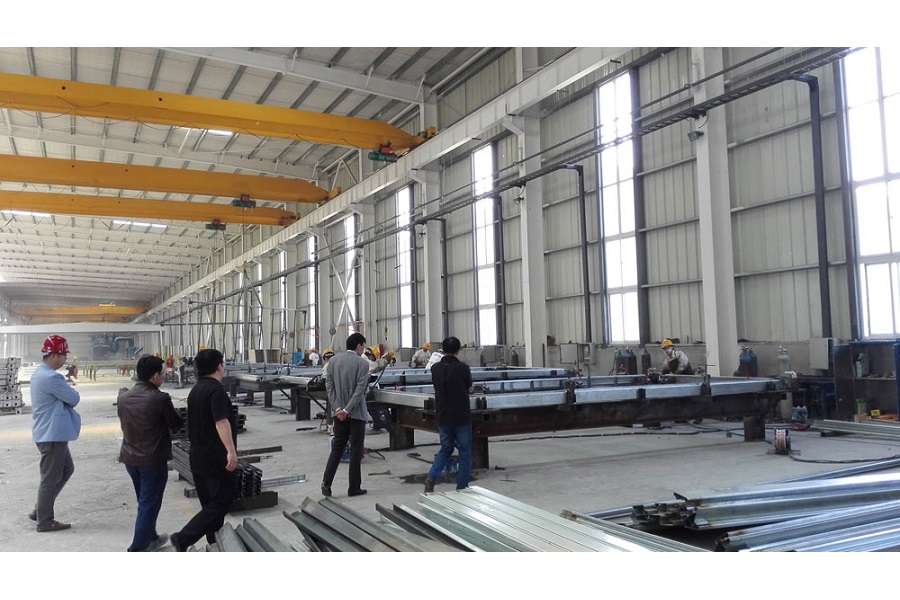

The steel structure components are made in factory, which reduces the workload on site, shortens the construction period, and reduces the construction cost accordingly.

Shock Resistance

The roofs of steel structure factory are mostly sloping roofs, so the roof structure basically adopts a triangular roof truss system made of cold-formed steel members. After sealing the structural board and gypsum board, the light steel components form a very strong "board rib structure system". this structural system has a stronger ability to resist earthquakes and horizontal loads, and is suitable for areas with a seismic intensity of more than 8 degrees.

Wind Resistance

Steel structure buildings have light weight, high strength, good overall rigidity and strong deformation ability. The self-weight of the steel structure building is 1/5 of the brick-concrete structure, and the usable area is about 4% higher than the reinforced concrete house. It can resist the hurricane of 70m/s, so that life and property can be effectively protected.

Durability

The light steel structure residential structure is all composed of cold-formed thin-walled steel member system, and the steel frame is made of super anti-corrosion high-strength cold-rolled galvanized sheet, which effectively avoids the influence of corrosion of the steel plate during construction and use, and increases the service life of light steel members. The structural life can be up to 100 years.

Thermal insulation

The thermal insulation material mainly adopts glass fiber cotton, which has good thermal insulation effect. The thermal insulation boards for external walls can effectively avoid the "cold bridge" phenomenon of the walls and achieve better thermal insulation effects.

Sound insulation

The sound insulation effect is an important indicator for evaluating a residence. The windows installed in the light steel system are all made of insulating glass, which has a good sound insulation effect, and the sound insulation is more than 40 De.The wall composed of light steel keel and thermal insulation material gypsum board has a sound insulation effect of up to 60 decibels.

Eco-friendly

Dry construction is used to reduce environmental pollution caused by waste. 100% of the steel structure materials of the house can be recycled, and most of the other supporting materials can also be recycled, which is in line with the current environmental awareness.

Comfortable

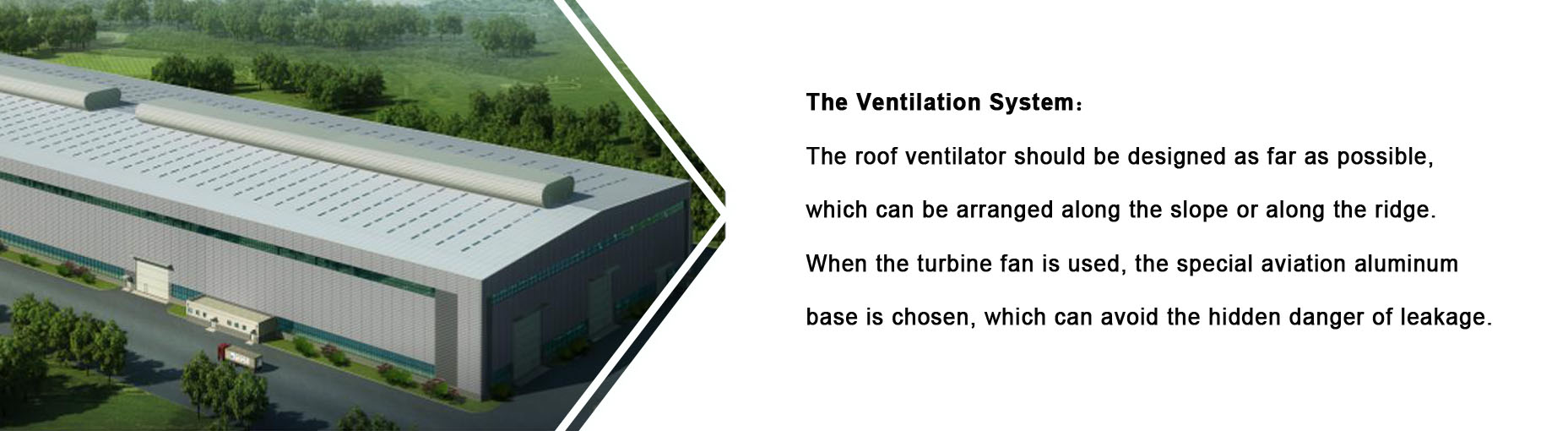

The wall of the light steel structure adopts a high-efficiency energy-saving system, which has a breathing function and can adjust the dry humidity of the indoor air; the roof has a ventilation function, which can form a flowing air space above the house to ensure the ventilation and heat dissipation requirements of the roof.

Fast

All of the steel structure building adopts dry work construction, not affected by environmental seasons. E.g. for a building of about 300 square meters, only 5 workers can complete the whole process from foundation to decoration within 30 days.

Energy saving

All adopt high-efficiency and energy-saving walls, which have good thermal insulation, heat insulation and sound insulation effects, and can reach 50% energy saving standards.

Application

GS housing has undertaken large-scale projects at home and abroad, such as Ethiopia’s Lebi Waste-to-energy Project, Qiqihar Railway Station, Hushan Uranium Mine Ground Station Construction Project in the Republic of Namibia, New Generation Carrier Rocket Industrialization Base Project, Mongolian Wolf Group Supermarket, Mercedes-Benz Motors production base (Beijing), the Laos National Convention Center, Involving large supermarkets, factories, conferences, research bases, railway stations... we have sufficient experience in large-scale project construction and export experience. Our company can send personnel to carry out installation and guidance training at the project site, eliminating customer worries.

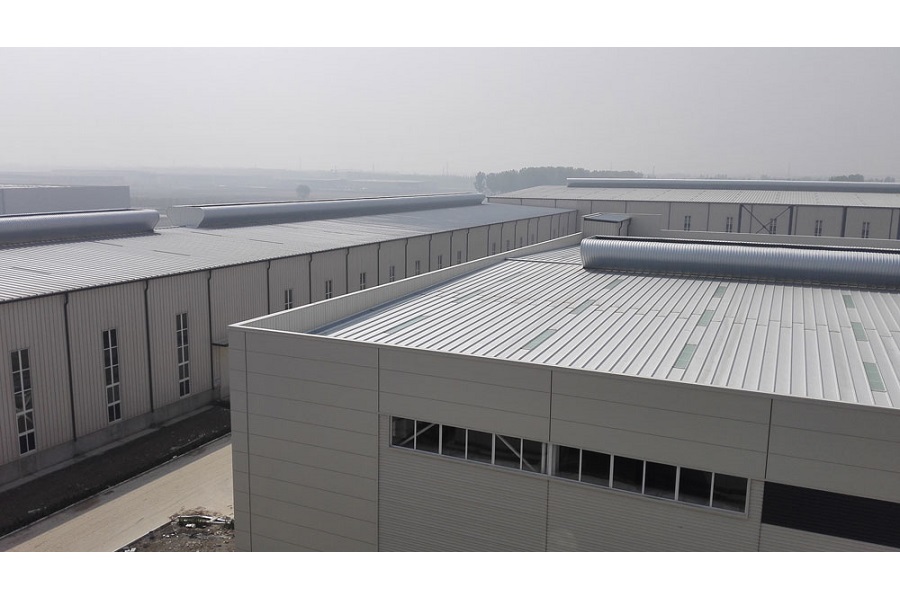

The workshop of GS housing is adopted the steel structure, as well as designed and build by ourself, let visit the inside after more than 20 years use.

| Steel structure house specifiction | ||

| Specifiction | Length | 15-300 meter |

| Common span | 15-200 meter | |

| Distance between columns | 4M/5M/6M/7M | |

| Net height | 4m~10m | |

| Design date | Designed service life | 20 years |

| Floor live load | 0.5KN/㎡ | |

| Roof live load | 0.5KN/㎡ | |

| Weather load | 0.6KN/㎡ | |

| Sersmic | 8 degree | |

| Structure | Structure type | Double slope |

| Main material | Q345B/Q235B | |

| Wall purlin | Material:Q235B | |

| Roof purlin | Material:Q235B | |

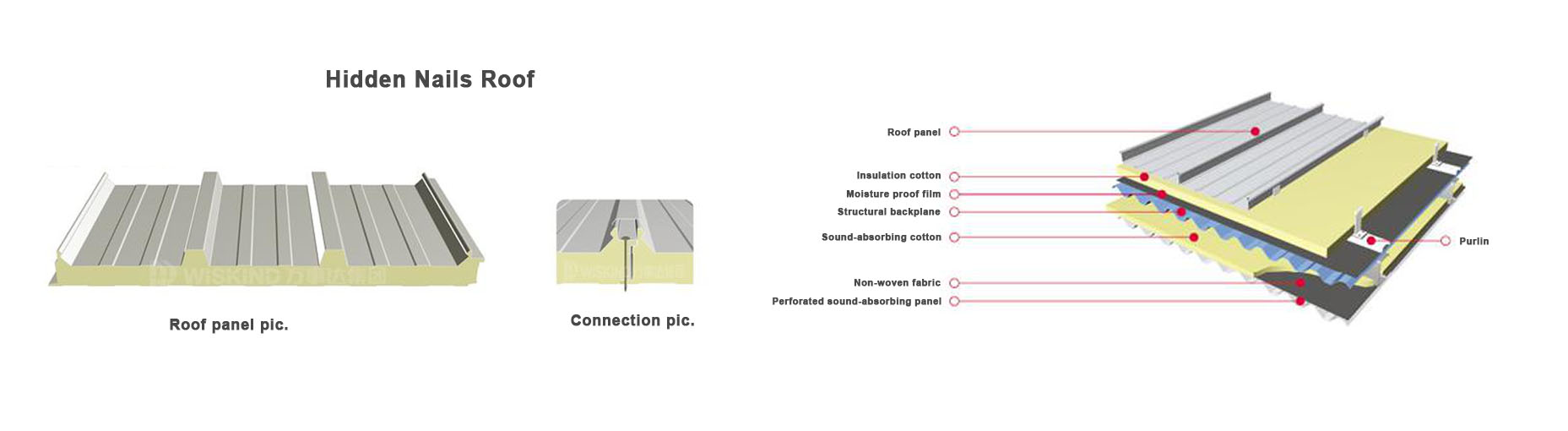

| Roof | Roof panel | 50mm thickness sandwich board or double 0.5mm Zn-Al coated colorful steel sheet/Finish could be choosen |

| Insulation material | 50mm thickness basalt cotton, density≥100kg/m³, Class A Non-combustible/Optional | |

| Water drainage system | 1mm thickness SS304 gutter, UPVCφ110 drain-off pipe | |

| Wall | wall panel | 50mm thickness sandwich board with double 0.5mmcolorful steel sheet, V-1000 horizontal water wave panel/Finish could be choosen |

| Insulation material | 50mm thickness basalt cotton, density≥100kg/m³, Class A Non-combustible/Optional | |

| Window & Door | window | Off-bridge aluminium,WXH=1000*3000;5mm+12A+5mm double glass with film /Optional |

| door | WXH=900*2100 / 1600*2100 / 1800*2400mm, steel door | |

| Remarks: above is the routine design, The specific design should be based on the actual conditions and needs. | ||